French, Handmade, Ceramic Plateware & Accessories

Made in France & Stocked in the USA.

Please contact us for more information, samples, quotations and/or to meet for a presentation.

Hospitality Catalog

Quick View:

Research & Custom Collections

From Raw to Fired

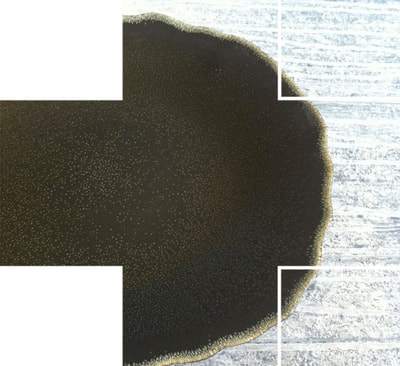

When kilns reach ‘grand feu’, their peak temperature at 2850F, the item in raw stoneware is transformed into its final shape and into the world of color.

In all circumstances, the fire is the key player in how the final shape, or misshape even, of each batch turned out of the kiln. It decides which nuance of colours result from the glazes combining and interacting with each other, a true alchemy in fact.

In the early hours, when opening the kiln, the magic is revealed.

Satisfaction or disappointment of the ceramicists…

Each item is unique :”not completely the same, not really different.” And we kind of know why.

The Luxury of Time

A nice objet crosses the time and resists it. At first, through its natural and strong material. But also and mainly because it required time and patience to be shaped.

Subtle and precise gestures.

Exigency

To the hidden details.

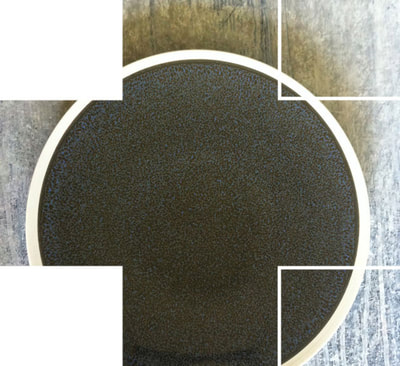

Material

During this ‘grand feu’ firing at 2850F, the clays that make up its refined body become vitrified (the state at which the china and glaze melts and fuses together to form non-porous ware) and allows stoneware to reach the status of ‘noble ceramic”.

We could list all the reasons why stoneware gets this distinction but this would be long but it is unique to Jars. It is certainly the most resistant and the most natural ceramic material.

Thanks to this high fire and vitrification process stoneware recalls how rock was formed some millions of years ago with the trilogy of “earth, water and fire”.

As if it was a living thing stoneware comes from nature and is returned to it.

Handmade

At Jars all our making, glazing, finishing and handling, and know-how of the material and even its hazards are the basics of a long learning process. Our hand-made skills are evident throughout :

In making a perfectly refined clay mix.

In casting the pieces.

In sponging and fettling edges and rims.

In applying the colored glaze.

In stacking ware in the kilns and taking it out.

For sorting by touch, feel and sight to control quality. So many of these workshop secrets are proudly shared between one ceramicist to another.

When kilns reach ‘grand feu’, their peak temperature at 2850F, the item in raw stoneware is transformed into its final shape and into the world of color.

In all circumstances, the fire is the key player in how the final shape, or misshape even, of each batch turned out of the kiln. It decides which nuance of colours result from the glazes combining and interacting with each other, a true alchemy in fact.

In the early hours, when opening the kiln, the magic is revealed.

Satisfaction or disappointment of the ceramicists…

Each item is unique :”not completely the same, not really different.” And we kind of know why.

The Luxury of Time

A nice objet crosses the time and resists it. At first, through its natural and strong material. But also and mainly because it required time and patience to be shaped.

Subtle and precise gestures.

Exigency

To the hidden details.

Material

During this ‘grand feu’ firing at 2850F, the clays that make up its refined body become vitrified (the state at which the china and glaze melts and fuses together to form non-porous ware) and allows stoneware to reach the status of ‘noble ceramic”.

We could list all the reasons why stoneware gets this distinction but this would be long but it is unique to Jars. It is certainly the most resistant and the most natural ceramic material.

Thanks to this high fire and vitrification process stoneware recalls how rock was formed some millions of years ago with the trilogy of “earth, water and fire”.

As if it was a living thing stoneware comes from nature and is returned to it.

Handmade

At Jars all our making, glazing, finishing and handling, and know-how of the material and even its hazards are the basics of a long learning process. Our hand-made skills are evident throughout :

In making a perfectly refined clay mix.

In casting the pieces.

In sponging and fettling edges and rims.

In applying the colored glaze.

In stacking ware in the kilns and taking it out.

For sorting by touch, feel and sight to control quality. So many of these workshop secrets are proudly shared between one ceramicist to another.

Since 1857

From its roots in horticultural pottery through to today’s much sought-after contemporary tableware collections in glazed stoneware, Jars’ history spans more than a 150 years…

Since it was founded by Pierre Jars, the traditional craft of potters’ skills passed down the generations still lives on today with the related making secrets of their forebears being closely guarded.

This rich skills resource has earned Jars EPV status (Entreprise Francaise du Patrimoine Vivant (French Companies of Living Heritage).

Instinctive Freedom

An inspired and vibrant creativity:

Full of ingenuity.

That combines imagination and elegance,

That reuses, reinvents, experiments,

That leaves things to chance, to trial and error.

Ecology

We like nature for its simplicity, its continuing renewed source of inspiration.This is why, in a small way but with conviction, we commit in all our work areas to choices that care for the environment, for example:

From its roots in horticultural pottery through to today’s much sought-after contemporary tableware collections in glazed stoneware, Jars’ history spans more than a 150 years…

Since it was founded by Pierre Jars, the traditional craft of potters’ skills passed down the generations still lives on today with the related making secrets of their forebears being closely guarded.

This rich skills resource has earned Jars EPV status (Entreprise Francaise du Patrimoine Vivant (French Companies of Living Heritage).

Instinctive Freedom

An inspired and vibrant creativity:

Full of ingenuity.

That combines imagination and elegance,

That reuses, reinvents, experiments,

That leaves things to chance, to trial and error.

Ecology

We like nature for its simplicity, its continuing renewed source of inspiration.This is why, in a small way but with conviction, we commit in all our work areas to choices that care for the environment, for example:

- We recycle water and china clay mixes.

- We recycle exhaust heat from the kilns

to use in the biscuit dryers.